Subteams

The complex internals of the submarine are split into six major systems. Each technical team is responsible for the design, manufacturing, assembly, and testing of their individual system, as well as interfacing with the other five systems. There are also three additional support teams that assist the technical teams.

TEchnical Subteams

-

The Propulsion Team designs and manufactures the propeller and its accessories, including the blades, hub, and tail cone. The propeller must be designed to give the most overall thrust to the submarine, while taking into consideration system complexity, drag reduction, and resource allotment. To achieve this optimal design, members are trained to use the parametric analysis tool OpenProp.

The team is currently working on integrating a variable pitch propeller (VPP) system that will electronically adjust the angle of the blades throughout the race and increase performance. The Propulsion Team must work closely with the Electronics and Drivetrain Teams for the VPP design and to ensure they are efficiently using the pilot’s power output to propel the submarine.

-

The Electronics Team works to develop electrical systems that reduce strain on the pilot and optimize the submarine’s performance. Their systems involve a variety of sensors, actuators, circuit boards, and batteries, as well as developing ways to completely waterproof these components.

Our Electronics Team is currently focusing on an electrical controls system and a variable pitch propeller, which means members work closely with the Controls and Propulsion Teams. They are also creating their own data logging system to accrue useful information about the performance of the submarine.

This team is always striving to work with the other systems to integrate more robust and effective electrical systems throughout the sub.

-

The Hull Team designs and fabricates the submarine’s hull, window, chassis, and control surfaces to be as hydrodynamic and ergonomic as possible. Members of the hull team are experienced at using the Composite Shop, SolidWorks, and Computational Fluid Dynamics softwares (CFD).

Subwoofer, our most recent submarine, has a hull fabricated from resin-infused carbon fiber. Along with its hatch, the top panels of the hull are designed to be completely removable for ease of access into the submarine’s internal systems. This makes installing and fixing the various subsystems quick and easy. Emphasis was also put on ease of manufacturability while fabricating this hull: while we outsource the chassis, the submarine’s panels are made completely in-house.

Each submarine is generally used for two competitions over two years. In the second year, the Hull Team focuses on refining its various components — this year, there is an emphasis on ensuring rigidity of the hull and comfort for the pilot!

-

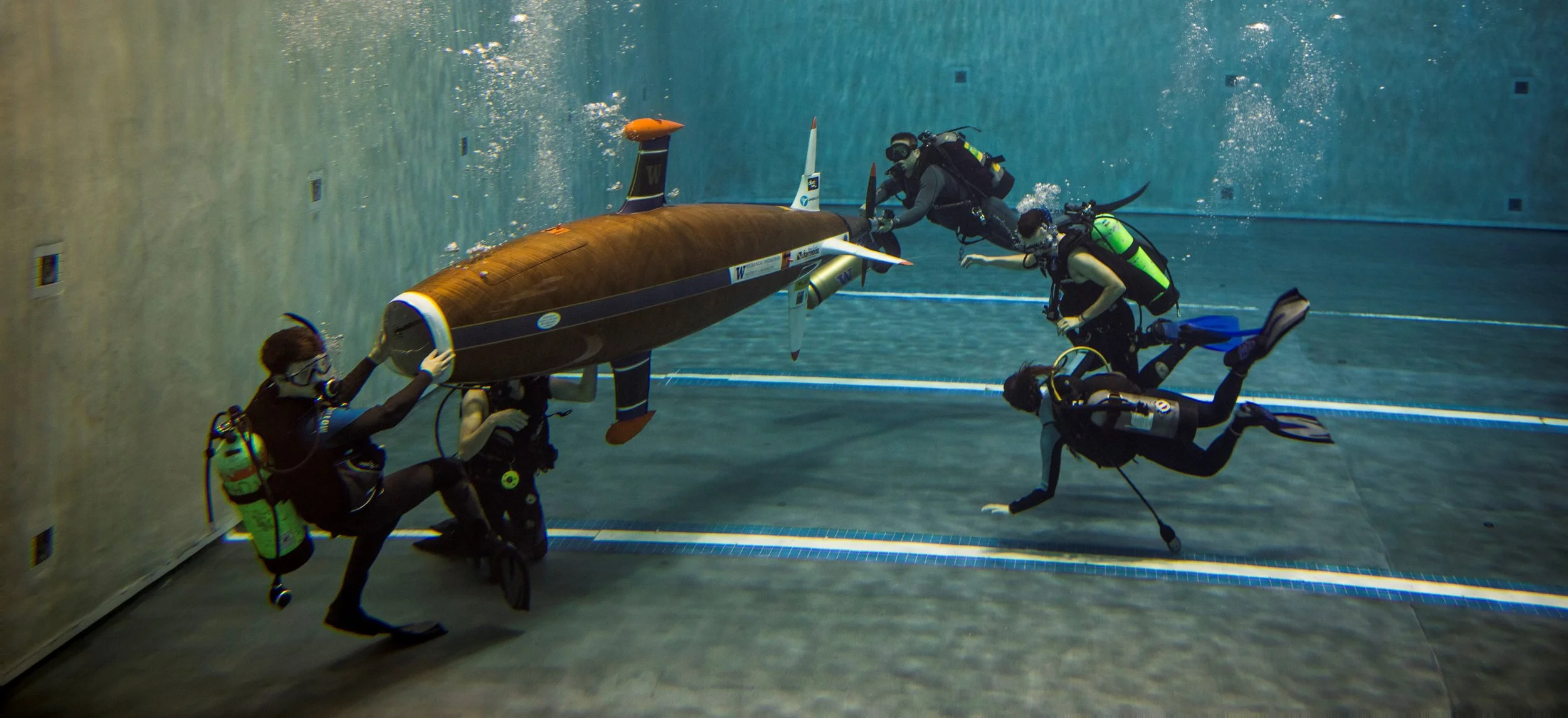

The Safety Team designs a system that keeps the pilot and the various support divers safe throughout the testing and competition process. The release of an emergency lever on the control joysticks —known as a dead-person switch — activates a visual alarm and a quick-release latch on the hatch. If any part of the submarine malfunctions or the pilot loses consciousness, this system signals the rescue divers and the pilot can be quickly evacuated.

The Safety Team is a small but critical aspect of the submarine, and their design philosophy is focused on reliability and simplicity.

-

The Drivetrain Team creates the connection between the pilot and the propeller. They design a bicycle-like system that transfers the pilot’s pedaling into the rotation of the propeller. Underdawg’s drivetrain consists of an aluminum frame that uses a chain to connect the pedals to a small sprocket — much the same as a bike. This small sprocket is then connected to a series of axles and bevel gears that in turn rotate the driveshaft, a long aluminum rod that runs to the back of the sub and turns the propeller.

The goal of the Drivetrain Team is to accommodate all of these components in a fairly limited space while still keeping the efficiency as high as possible. The drivetrain is the sub’s largest and most mechanically-oriented system.

-

The Controls Team is responsible for the system that enables the pilot to steer the submarine underwater. The pilot uses a joystick to control the sub in pitch (up/down) and yaw (left/right) by moving four fins attached to the outer hull. This means our Controls Team must design and manufacture ways to transfer the motion of the pilot’s joystick to the rotation of these fins.

This year, Controls is working on both an electrical and a mechanical system. The electrical system will use servos (rotational motors) and pulleys and will be the primary method of control, while the mechanical system is used as a backup.

The electrical and mechanical systems must be designed so they fit in the tight space at the back of the sub while still being easily usable and adjustable. Because of these constraints, the controls system is the most intricate system within the submarine.

Support teams

-

The Business Team is in charge of all of the administrative duties for the team. This includes running the social media, the website, making the merch, and planning events. The business team also works hard behind the scenes to ensure the club runs smoothly by purchasing all materials that the subteams need, building and maintaining a relationship with sponsors, and putting together the logistics to ship the submarine to competition.

-

The Manufacturing Team is where designs become reality. This team consists of skilled machinists who spend time in the shop manufacturing parts for the technical teams. They are generally responsible for manufacturing the more intricate parts of the sub, and are often part of other technical teams.

-

The Dive Team consists of several AAUS-certified scientific divers. They provide support for the pilot and technical teams during underwater tests and at the competition. Dive Team members are generally also members of other technical teams.